Tinted UV Protective Finish

- Very water and dirt resistant

- Reduces wood swelling and shrinkage

- Resists growth of algae, mildew and fungal

- Microporous, breathable finish which does not crack, peel, flake or blister

- No sanding necessary for future applications

- Looking for a clear finish? View UV-Protection Oil

Please Note: Colours were developed to appear in harmony with their respective wood species e.g. 426 Larch for Larch wood projects. The wood’s natural colour and character will influence the final result. Plus, the darker the colour, the stronger the UV-resistance. Please always trial apply!

*See tips and suitability for further guidance.

Finishes

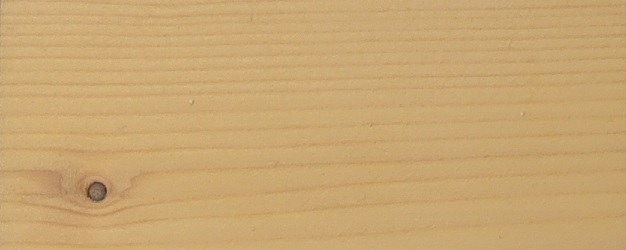

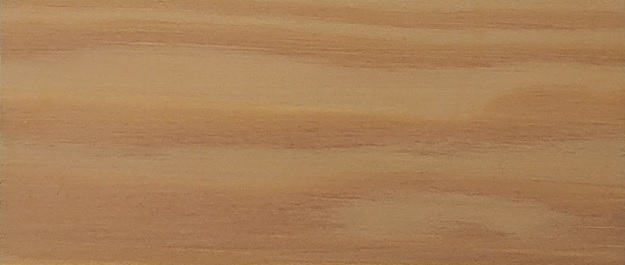

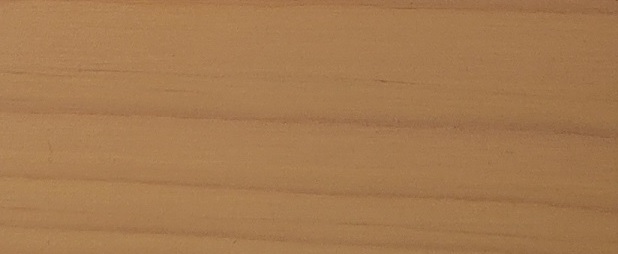

Spruce (Satin), Oak (Satin), Larch (Satin), Douglas Fir (Satin), Cedar (Satin), Natural (Satin), Light Red Cedar (Satin), Light Oak (Satin)

Application Tool

Osmo Flat Brush or Osmo Microfibre Roller

Recommended Use

Vertical wood surfaces in outdoor areas

Recoat

One coat, when signs of wear become visible

Sizes

5ml, 125ml, 750ml, 2.5L

Dry Time

12 hours

Clean Up

Osmo Brush Cleaner

Coverage

18m²/L with one coat

Coats

2 coats

Care

Osmo Spray Cleaner

Surface Preparation

Wood surface must be clean, dry and frost-free (moisture content max. 20%). UV-Protection-Oil Tints is ready to use. Do not thin. Stir well using a flat stirring stick or spatula before use. Ideally, surfaces are sanded no finer than a P120 grit grade of sand paper. Sanding to finer grades will reduce required absorbency.

If possible, and if the wood is absorbent, please apply first coat to all sides before installation. Fresh wood containing natural wood ingredients /extractives (eg: Cedar, Teak, Mahogany or Iroko) are often less absorbent and need to weather off first before applying the product. Please refer to website ‘Suitability’ section for more details. Weathering helps ingredient rich wood become more absorbent and the wood finish adheres optimally.

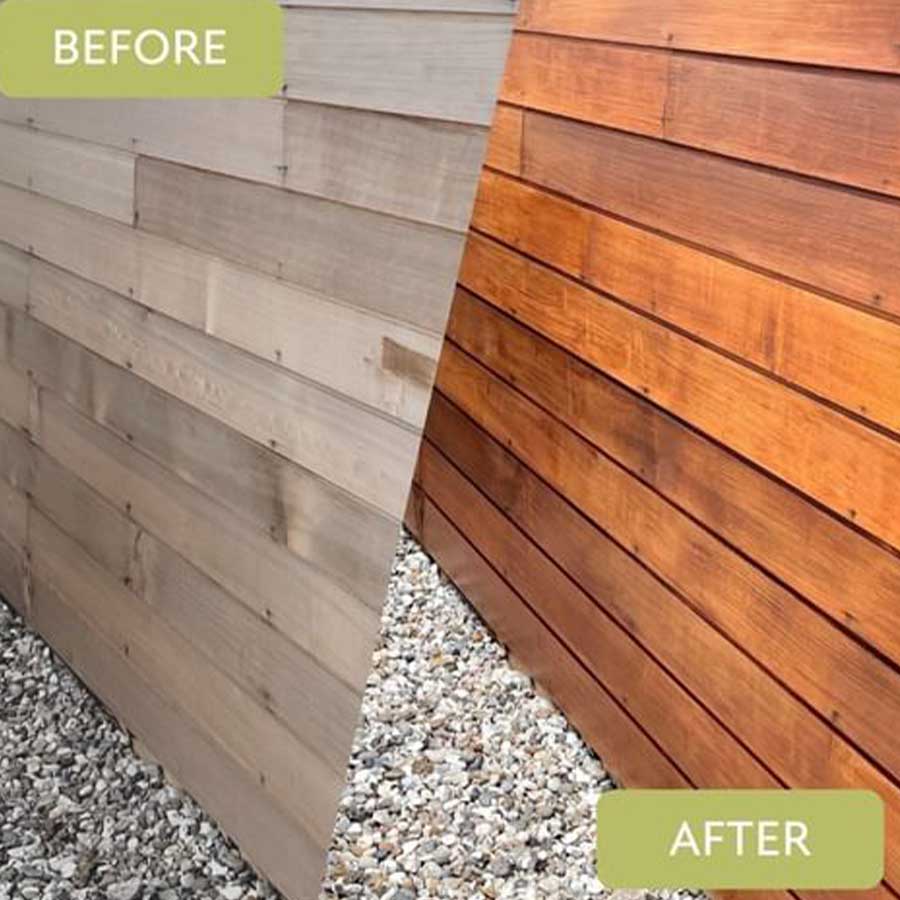

For renovation works, clean old microporous stains thoroughly – if necessary sand lightly. Clean and restore already greyed or weathered wood at the same time with Osmo Wood Reviver Power-Gel. Old paints and lacquers must be completely removed. As a general rule, wear a dust mask during sanding works. To maintain absorbency, avoid sanding surfaces finer than a P120 grit. Weather ingredient rich wood after sanding.

The finished surface is influenced by several factors, including the condition of the wood. Therefore, a trial application is always required, especially for unfamiliar surfaces.

Soft wood species like Pine or Spruce are more prone to blue stain, rot and insects. If desired, pre-treat these soft woods if possible on all sides with Osmo WR Base Coat.

Method of Application

With Osmo Flat Brush or Osmo Microfibre Roller, apply thinly along the wood grain and spread well.

Allow to dry for approx. 12 hours under good ventilation.

Then apply the second coat.

Alternatively the second coat can also be carried out with UV-Protection-Oil Extra Clear.

When recoating colour treated surfaces, or for renovation works, one coat applied to the clean and dry surface is usually sufficient.

Note

Depending on the degree of weathering, apply one coat of Osmo UV-Protection-Oil Tints to the cleaned and intact finish after approx. 3-4 years.

For areas exposed to strong weathering, such as horizontals, weatherboard, post caps or window sills, please expect significantly shorter renovation intervals.

Vertical elements mounted onto horizontal wood should have at least a 15 degree angle. Sharp edges must be rounded (radius > 2 mm).

If the greying process has already begun, degrey the surface with Osmo Wood Reviver Power Gel and refinish with 2 coats of Osmo UV-Protection-Oil Tints.

To achieve the UV protection factor 12, it is necessary to apply 2 coats of UV-Protection-Oil Tints. With only one coat on untreated wood, the life of the coating is significantly shorter.

Osmo UV-Protection-Oil Tints is furnished with biocides and therefore it is only to be used in outdoor areas. The added active ingredients delay or minimise the risk of algae and fungal attack. For effective protection, two coats are to be carried out. In accordance with the latest technical research, permanent protection against algae and fungal attack cannot be provided.

Osmo UV-Protection-Oil Tints 429 Natural protects wood nearly invisibly. The natural wood tone is preserved using a white coloured tint. When applied correctly, it does not enhance the the natural colour tone of the wood (no permanent wet effect).

On dark/reddish wood species, Osmo UV-Protection Oil Tints 429 Natural is visible as slightly white chalky surface. Over application of Osmo UV-Protection-Oil Tints 429 Natural may also appear slightly white and chalky, especially over very textured surfaces. Always remove excess white pigment before allowing the surface to dry. A trial application is always recommended.

Using power washers will severely decrease the coverage of the finish and general or multi-purpose cleaners will increase the frequency of maintenance and recoating.

Care

Regular Cleaning: Damp cleaning with Osmo Spray-Cleaner.

Occasional Maintenance: If necessary, intensive cleaning and refreshing using Osmo Wood Reviver Power Gel or Osmo Gard Clean.

Recoating: Simply re-apply one coat onto the clean and dry surface when signs of wear become visible.

Download the PDF product information and safety data here:

Recommended

For all other wood types not mentioned, always trial apply first.

- Oak: UV-Protection Oil Tints 425 Oak (for a darker shade) and 429 Natural (for a lighter shade) are optically suitable.

- Beech

- Ash

- Alder

- Birch

- Thermowood and Thermally Modified Timber (TMT): prone to grey very fast and therefore application of a tint/colour is recommended within the first two weeks after processing. Always trial apply the tint/colour to reach a harmonious colour tone with Thermowood / TMT.

Also Recommended

For the following wood types, WR Base Coat is recommended before use.

- Douglas Fir: UV-Protection Oil Tints 427 Douglas Fir is optically suitable.

- Pine: UV-Protection Oil Tints 424 Spruce is optically suitable.

- Spruce: UV-Protection Oil Tints 424 Spruce is optically suitable.

- Accoya®

- Kebony®

Recommended After Weathering Period

For the following wood types, a weathering period is recommended. New or sanded wood requires at least 12 weeks (approximate) exposure to the exterior elements before application.

After the weathering period, it’s generally recommended to de-grey the surface with Osmo Wood Reviver Power-Gel and clean the surface from the extractive content before application, always trial apply!

For all other ingredient-rich hardwood species not mentioned may require a varied period of exposure. Please contact us for further information.

- Cedar: UV-Protection Oil Tints 428 Cedar is optically suitable.

- Iroko

- Mahogany

- Teak

- Walnut

- Ipe

- Merbau

- Wenge

- Rosewood

- Sycamore

- Sapele: 3-4 weeks exposure

- Larch: Approx. 2 weeks exposure. Application of WR Base Coat is recommended before use. Then, UV-Protection Oil Tints 426 Larch is optically suitable.

- Pressure-Impregnated Wood: Approx. 12 weeks exposure to heavy rain (winter periods) or approx. 6 months exposure to light rain (summer periods) to wash out the salts used for impregnation.

Important: please check and ensure moisture content is below 20% prior to application.

Not Recommended

- Green Oak: moisture content is often above the maximum 20% recommended.

- Idigbo: contains yellow dyes which leaches when the wood becomes wet and stains when in contact within iron.

- Flat surfaces: such as decking, window sills, garden tables, seats, benches and other joinery whereby rain is able to remain on the surface for long periods of time.

- UV-Protection Oil Tints 429 Natural: not recommended for use on ingredient-rich (dark/reddish) wood species because it is visible as slightly white chalky surface. Remove white pigments from surface before leaving to dry. A trial application is always recommended.

- Other: woods treated with a varnish, lacquer or other surface coatings must be completely sanded before use.

OSMO FLAT BRUSH

Made with high quality synthetic bristles with soft tips which gives fine control in achieving the desired effect. Exceptional coverage capacities which produce professional looking results every time. Available in 25, 50, 60 and 100 mm sizes.

OSMO SMALL ROLLER SET

Microfibre roller and 60mm natural bristle brush set to ensure high coverage allowing you to apply thinly, thoroughly and evenly along the wood grain and spread well. For first application, two coats is recommended onto a clean and dry surface. For renovation, just one coat is necessary.

Top Tips:

- Stir well using a flat stirring stick or spatula. Failure to mix the colour and all ingredients could lead to an increased patchiness.

- Ideally the new surface will be finished to a final P120 grit sand paper grade. This is the optimal grade for applying Osmo UV Protection-Oils.

- For ingredient-rich wood species (eg: Cedar, Iroko, Teak, Mahogany etc.), please allow 12 weeks weathering prior to application. Weathering will improve absorbency for the Osmo product to penetrate in to the wood. If the wood has greyed after weathering, use Osmo Wood Reviver Power Gel to refresh the colour once more. Avoid refreshing colour through sanding as this will reveal fresh wood ingredients, and the surface will need to be weathered once more.

- Osmo UV Protection-Oil Tints 429 Natural is not recommended for use on ingredient-rich (dark/reddish) wood species because it is visible as slightly white chalky surface. A trial application is always recommended.

- Over application of Osmo UV Protection-Oil Tints 429 Natural may lead to the inherent white pigments becoming visible. The product may appear more white on very textured / rough sawn surfaces. Remove excess white before allowing the surface to dry.

- UV-Protection Oils perform optimally on vertically structured timber. For horizontal sections there will be more maintenance. On horizontal sections, ensure at least a 15 degree angle to facilitate water run-off. Sharp edges must be rounded (radius > 2 mm).

- Over application and/or low ventilation can increase the drying times.

- UV rays from the sun help to break down protective lignin surrounding the fibres in the wood. Moisture also helps to deplete the lignin and the wood fibres begin to grey naturally. Osmo UV-Protection Oils delay the greying effect 12 x more effectively than bare timber.

- Osmo UV-Protection-Oil Tints are furnished with active biocides to help protect the film coating against the effects from mould, algae and fungal attack. The added biocides do not prevent mould, algae and fungal growth forming on the coating.

- Some timbers like Oak and Chestnut are notoriously rich in natural tannins and these ingredients can blacken surfaces when exposed to moisture, sunlight and iron oxides (eg from wire wool). Horizontal sections are more prone to discolouration whereby moisture can accumulate then escape through a breathable coating like Osmo. As the moisture escapes it lowers the risk of warping however, natural tannins can migrate to the surface and cause some staining. To help reduce this, try to clean the first signs of tannin spots away from the coating with a damp cloth. Over time, the tannins will deplete and the discolouration will be less problematic. Choosing a darker coloured Osmo UV-Protection oil tint can also help to mask discolouration.

- Many wood species (eg Larch) contain water-soluble coloured extractives which may leach out naturally when weathered. Bare weathered wood can often be refreshed using Osmo Wood Reviver Power Gel prior to treatment. Always trial apply first.

Additional Information:

- Approx. coverage: 18m²/L with one coat

- No. of coats: 2

- Ideal application temperature: +10°C to 35°C

- Drying time: 12hrs.

- Sizes: 0.125L, 0.750L, 2.5L

All exterior woods grey into a patina colour over time, however UV-Protection Oil Tints have been developed to maintain the wood’s natural colour with the use of pigments to optimally match the wood’s natural characteristics.

Ideal for windows, doors, cladding, fencing and other vertically structured joinery (not recommended for completely flat surfaces such as decking).

Natural oil-based and microporous ( breathable) finish does not crack, flake, peel or blister. Water and dirt resistant, moisture regulating and reduces wood swelling and shrinkage.